Building the Lightest Mazda Rotary Engine: Precision and Billet Components

- Authors

- Published on

- Published on

- Name

- By Dushyant

- (@dishs)

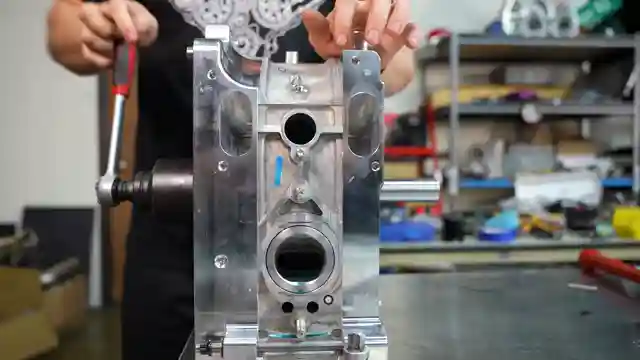

In this episode of Rob Dahm, the team is hard at work on creating the lightest rotary engine ever seen, based on a Mazda design. With a focus on precision and innovation, they delve into the world of billet components, upgrading tension bolts, and reimagining the traditional two-rotor setup. As they tackle challenges like bearing installation and clearance issues, Rob Dahm's team showcases their dedication to pushing boundaries in rotary engine technology.

With a keen eye for detail, they meticulously assemble the engine, experimenting with different components and techniques to optimize performance. Despite facing setbacks and the need for adjustments, the team remains determined to achieve their goal of creating a powerhouse engine that defies expectations. Through careful testing and fine-tuning, they aim to unleash the full potential of their creation and set new standards in the world of rotary engines.

Image copyright Youtube

Image copyright Youtube

Image copyright Youtube

Image copyright Youtube

Watch We Build the BILLET Turbo 1 ROTOR! Almost Entirely ALUMINUM on Youtube

Viewer Reactions for We Build the BILLET Turbo 1 ROTOR! Almost Entirely ALUMINUM

Viewer praises Rob's dedication and updates over the years

Tip for shrink fitting parts

Excitement for the project's return

Interest from non-rotary enthusiasts

Suggestions to put the engine in a sport bike, UTV, motorcycle, or airplane

Comments on DLC coating for rotor and molecular chemistry for more power

Mention of Haltech's involvement in the assembly

Comparison to other rotary builds

Technical comments on CNC machines and Mitutoyo drop gage

Various suggestions for applications such as go kart, buggy, motorcycle, and longboard

Related Articles

Rob Dahm: Shiny 3D Scanner, Clutch Kit, and 3D Printed Car Ducts

Rob Dahm showcases the Shiny 3D scanner's advanced capabilities, discusses a new clutch kit, and introduces Eight Sleep's innovative technology. The team delves into 3D printing ducts for the car, highlighting challenges and successes in the process.

Rob Dahm's Team Revs Up Three-Rotor Engine for Pikes Peak Success

Rob Dahm's team prepares the three-rotor engine for Pikes Peak, overcoming challenges like rotor damage and seal issues. With meticulous rebuilding and innovative techniques, they enhance performance for the upcoming race.

Building the Lightest Mazda Rotary Engine: Precision and Billet Components

Rob Dahm's team works on creating the lightest Mazda-based rotary engine ever, focusing on billet components and precision assembly for optimal performance.

Reviving an Iconic Indie Car: Unveiling the Transmission Casing

Rob Dahm revives an iconic Indie Car, unveiling its versatile transmission casing. Discover the car's history, intricate mechanics, and the team's journey to restore it to its former racing glory.